![PDF] Mathematical models of flank wear using vibration amplitude ratio in drilling | Semantic Scholar PDF] Mathematical models of flank wear using vibration amplitude ratio in drilling | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/30deaa1f70d577c181f565c225a230440dbc392d/4-Figure2-1.png)

PDF] Mathematical models of flank wear using vibration amplitude ratio in drilling | Semantic Scholar

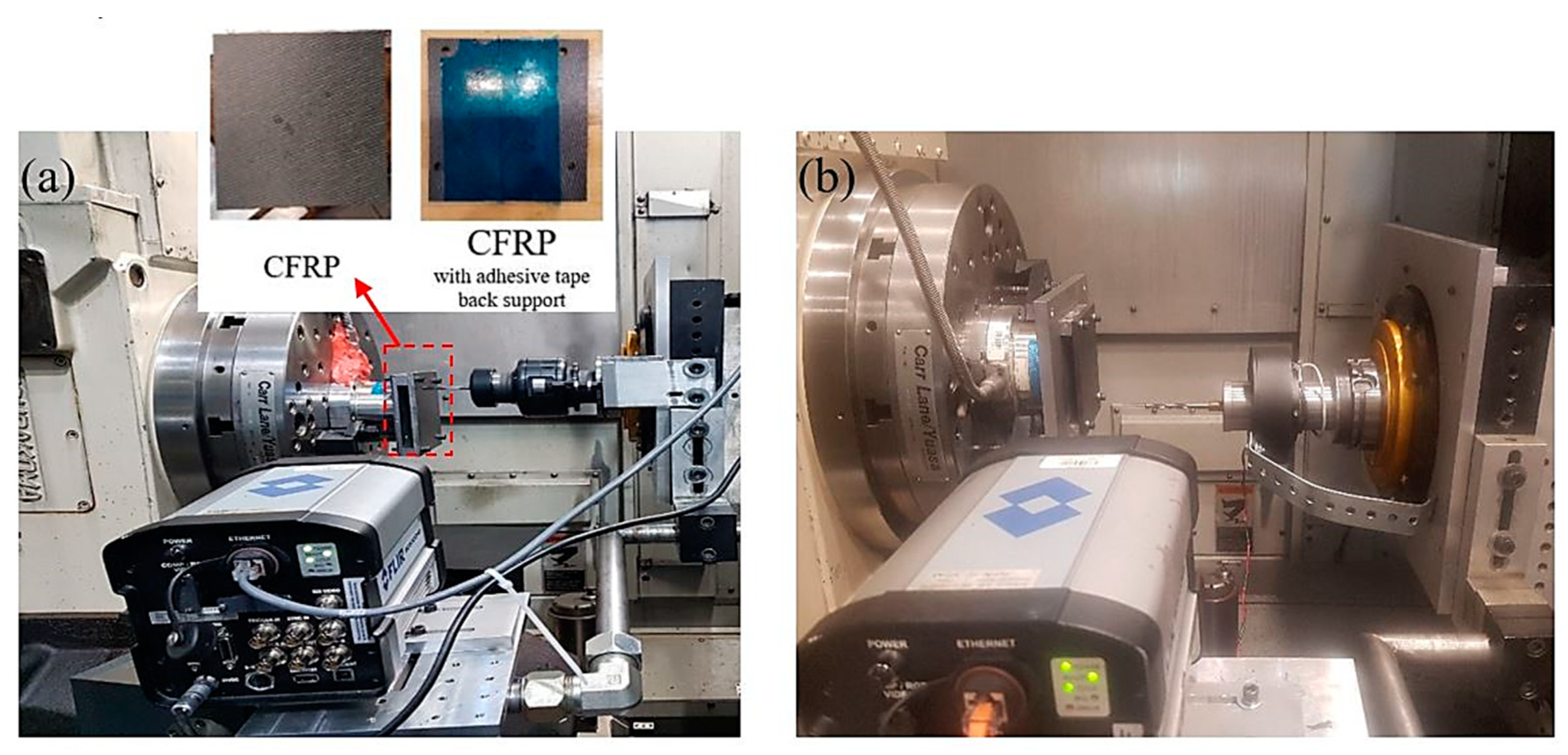

JMMP | Free Full-Text | Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer | HTML

Correlation between vibration amplitude and tool wear in turning: Numerical and experimental analysis - ScienceDirect

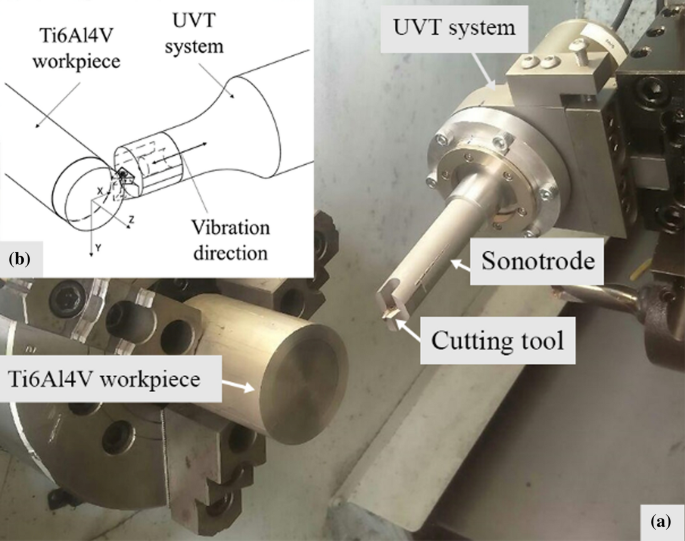

Wear Behavior of Ti6Al4V Surfaces Functionalized through Ultrasonic Vibration Turning | SpringerLink

Correlation between vibration amplitude and tool wear in turning: Numerical and experimental analysis - ScienceDirect

Development of an ANN model for prediction of tool wear in turning EN9 and EN24 steel alloy - Rahmath Ulla Baig, Syed Javed, Mohammed Khaisar, Mwafak Shakoor, Purushothaman Raja, 2021

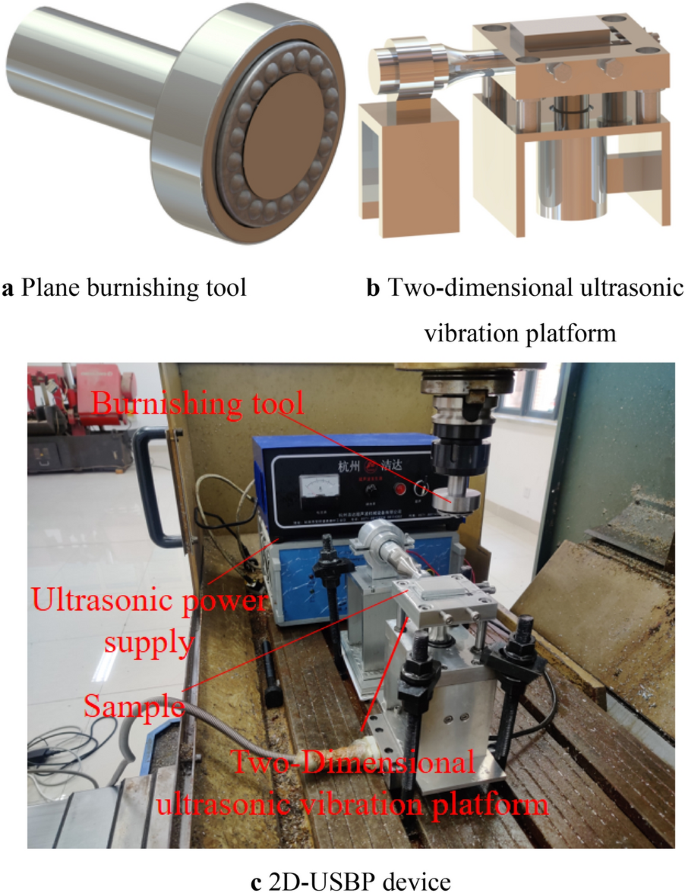

Investigation of Two-Dimensional Ultrasonic Surface Burnishing Process on 7075-T6 Aluminum | Chinese Journal of Mechanical Engineering | Full Text

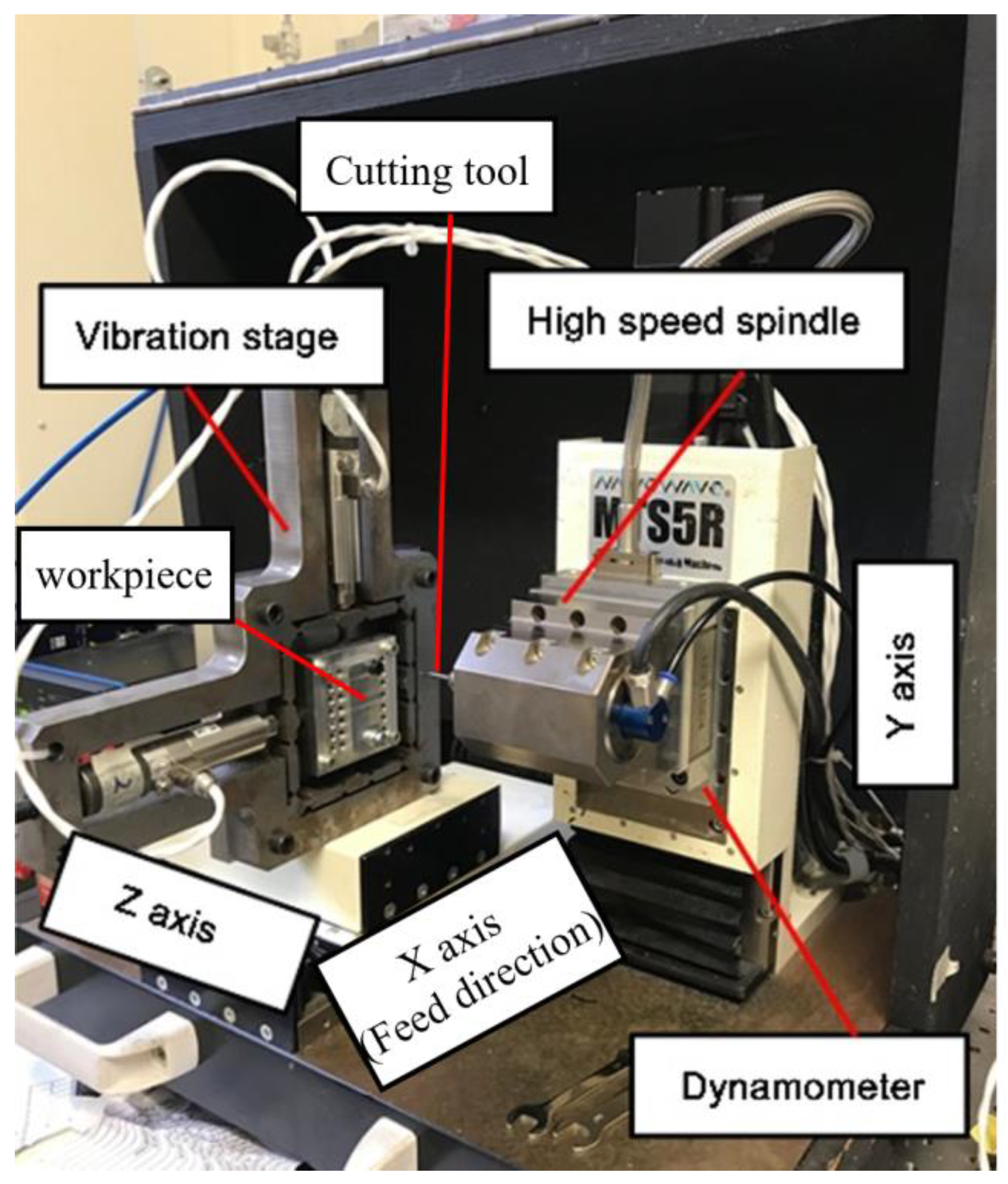

Experimental study on machinability improvement of hardened tool steel using two dimensional vibration-assisted micro-end-milling - ScienceDirect

Micromachines | Free Full-Text | Investigation on the Tool Wear Suppression Mechanism in Non-Resonant Vibration-Assisted Micro Milling | HTML

Effect of Tool Vibration on Flank Wear and Surface Roughness During High-Speed Machining of 1040 Steel | SpringerLink

Experimental set-up for wear contact between a cylinder and a rubber... | Download Scientific Diagram

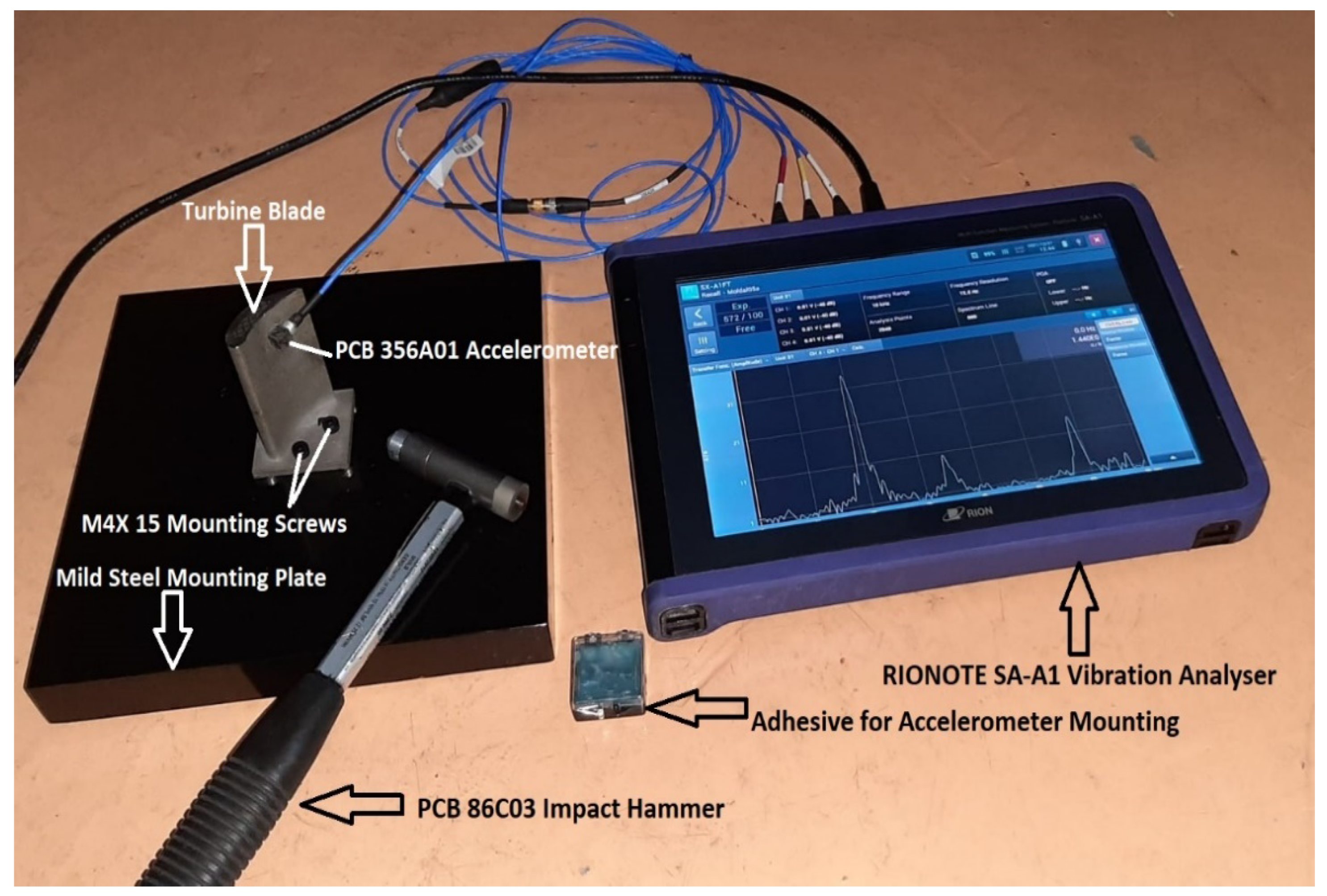

Metals | Free Full-Text | Experimental and Numerical Vibration Analysis of Octet-Truss-Lattice-Based Gas Turbine Blades

Elliptical vibration cutting of large-size thin-walled curved surface parts of pure iron by using diamond tool with active cutting edge shift - ScienceDirect

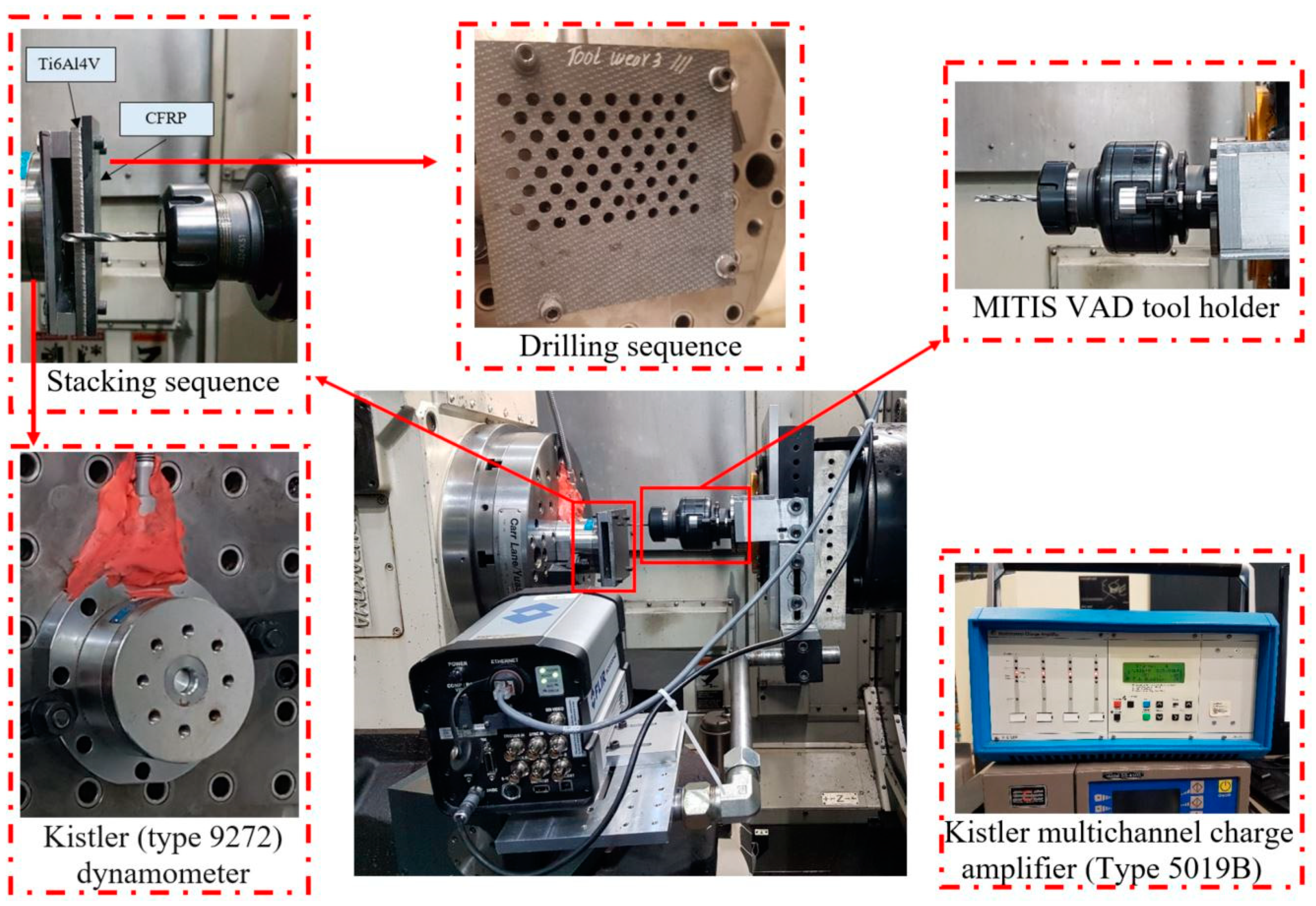

JMMP | Free Full-Text | An Investigation into Tool Wear and Hole Quality during Low-Frequency Vibration-Assisted Drilling of CFRP/Ti6Al4V Stack | HTML

Analysis of vibration signals to quantify displacement amplitude in the monitoring of vibration-assisted turning

The experimental set up for testing whether two vibration motors could... | Download Scientific Diagram

Milling Tool Wear State Recognition by Vibration Signal Using a Stacked Generalization Ensemble Model

Correlation between vibration amplitude and tool wear in turning: Numerical and experimental analysis - ScienceDirect